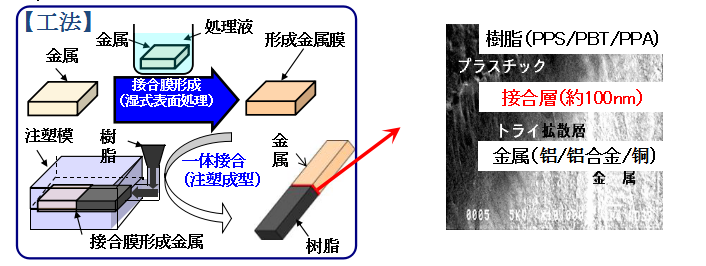

TRI treatment process

1. Strong bonding strength

The bonding film formed by the metal surface treatment makes the metal and the resin bond strongly, which is stronger than the intermolecular force of the adhesive.

2. High air tightness

The metal and resin are uniformly joined to give full play to high air tightness.

3. Can fit complex shapes

Because it can be adapted to complex shapes, the design is not restricted by the shape.

4. Excellent reliability

After injection molding, the joints have no surface damage in the subsequent processes (CNC processing, anodizing, etc.), ensuring high reliability.

5. Suitable for mass production

TRI film after TRI treatment can reach 1 month under certain storage conditions, so it can be mass produced.

|  |

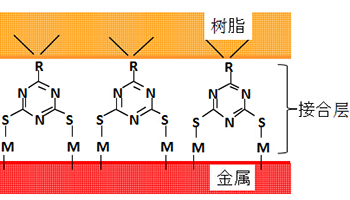

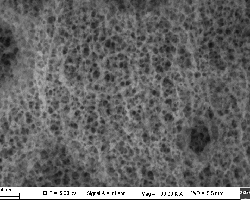

| Metal + bonding layer, bonding layer + resin chemical reaction link combination diagram | SEM photo of 6 series aluminum after TRI treatment |

Chemical reaction linkage refers to the formation of an oxide film with a thickness of 100-300nm on the surface of the pre-treated aluminum during the TRI process. The oxide film contains substances that can promote the combination of resin and metal, and produce chemical reactions under high temperature and pressure. , Make the resin and metal firmly bond, and produce a high sealing state.

2. TRI SYSTEM is a new type of pre-treatment process for nano-injection molding. It is researched and developed by Japan’s Toa Denka. Samsung mobile phone specifies the pre-treatment process for nano-injection. It has the following advantages:

1. The formation of nanopores on the metal surface and the formed bonding film are double guarantees of physical and chemical bonding, so that the metal and plastic are firmly combined;

2. Because the metal and plastic are evenly joined, a high sealing state will be produced, which can be effectively waterproof, and the waterproof level can reach IP69;

3. Because of the excellent bonding force, and the more uniform combination of metal and plastic, the microscopic gap is small after injection molding, which has a better preventive effect on poor acid discharge of nano-injection products;

4. The service life of the TRI film after TRI treatment in the vacuum sealed state is about 1 month, so it can be produced in stock and can meet the turnover of large quantities of materials.

5. Compared with other treatments (E, T, HK, etc.), the nano-injection products using TRI treatment have less interference to the antenna signal.

扫二维码用手机看

联系我们

中国广东深圳市沙井街道同富裕工业区中熙工业园A栋

Copyright © 深圳市金宏欣科技有限公司版权所有 粤ICP备16031021号